Reinforced Earth UK Reaches 50th year milestone

Reinforced Earth Company (RECo) UK celebrates its 50th year With nearly 70 million square meters installed worldwide, RECo UK, part of the Terre Armee Group is without doubt the global leader in the field of soil reinforced structural solutions. During 2024, RECo has started these celebrations by [...]

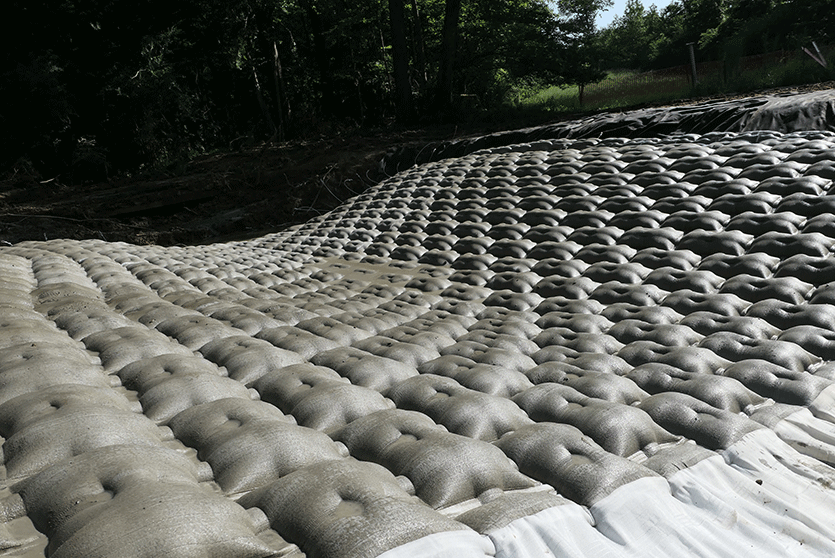

Terre Armee announces the acquisition of Synthetex

Terre Armée announces the acquisition of the American company Synthetex, based in Atlanta (Georgia, USA). With nearly 7 million square meters installed worldwide, Synthetex combines recognized expertise and production capacity in erosion and scour protection solutions, such as river, ports quays and coastal protection, pipeline protection using Hydrotex®, a [...]

Exegy® Low Carbon Concrete Products

Exegy by Reinforced Earth is the new global brand for our low carbon concrete products and RECo UK are very excited to be manufacturing retaining wall panels for a structure near Edinburgh with our precast partners Macrete Ireland Ltd. The low carbon concrete mix uses a very [...]

Environmental Product Declarations EPD’s and Carbon Calculator

Reinforced Earth have been awarded EPD’s on 2 of their products, that further demonstrates our environmental responsibility. Our geosynthetic solutions have always been held as having exceptional CO2 values and this further reinforces our case. T-Wall despite having no geosynthetic reinforcements, still demonstrates the outstanding properties of [...]

Terre Armée India builds the world’s tallest Reinforced Earth® structure

In September 2011, the town of Tindharia located in West Bengal, India experienced a massive landslide following an earthquake and heavy rainfall. The landslide significantly affected three locations – S1 (Height 34.9m), S2 (Height 102.8m) and S3 (Height 38.7m) – resulting in the collapse of a section of [...]

World-record bund test confirms Terre Armée’s capacity to innovate, leadership in soil-structure interaction

Reinforced Earth® rockfall bund withstands impact of 5000 KJ Three years of research subjected to a few seconds of truth The excitement was palpable at the Montagnole rockfall test site near Lyon, France on June 16. Three years of collaborative research combining the expertise of Terre Armée [...]

TerraLink®solution to stabilize slope and widen road

In the last quarter of 2018, cyclone Titli took a toll on Odisha state, located on the east coast of India. It caused severe damages including landslides in various locations on National Highway 59. Near Daringbadi - a tourist destination about 200 km away from the state capital [...]

Reinforced Earth® Headwalls for Wildlife Crossing

A new wildlife crossing bridge and six-lane roadway opened last week in Edmonton, Canada. Connecting the city’s ring road, the Anthony Henday Drive, with the northeast energy and industrial area, the Aurum Energy Park-Aurum Road Wildlife/Creek Crossing will reduce the daily commute for about 10,000 workers by about [...]

Reinforced Earth® walls for Jorf Lasfar Power Station

In Morocco, the Jorf Lasfar thermal power station features high-performing installations. Guaranteeing an availability rate of over 90%, it is one of the best performing power stations in the world. The facility enjoys a strategic geographic location thanks to its proximity to the Jorf Lasfar Port. An estimated [...]

Uganda: Extension of the Kampala Northern Bypass

In Kampala, at the Northern edge of Lake Victoria, Reinforced Earth South Africa (RESA) supplied Reinforced Earth® walls for the extension of the Northern Bypass. Designed in a semicircle and built between 2004 and 2009 across the northern suburbs of the city, the bypass aims to relieve traffic congestion in the city centre. In May 2014, the [...]

Transmission Gully Project

TechSpan arches and Reinforced Earth walls for New Zealand road project When completed, in May 2020, the Transmission Gully Project (TGP) will provide a new, 27 km long, four-lane motorway north of Wellington, New Zealand. This modern and safe main highway will bypass the coastal communities and space-limited [...]

Canada: Regina Bypass to open to traffic

23000 m2 of Reinforced Earth walls for largest transportation infrastructure project in Saskatchewan’s history The highway bypass of the City of Regina, capital of the Province of Saskatchewan in Canada, will open to traffic on October 29, 2019. The Regina Bypass is the largest transportation infrastructure project in [...]

Tierra Armada Chile S.p.A. helps rebuild Valparaiso

Precast walls and wave barriers to reconstruct and protect Chile's most important port damaged by earthquakes in 2015 The Port of Valparaíso is Chile’s most important container and passenger port. About 11 million tons of cargo, one million shipping containers, and more than 50,000 passengers pass through it [...]

Freyssinet Mexico and Tierra Armada Mexico join forces to rehabilitate Amecameca Bridge after devastating earthquake in Mexico City

Advantages of precast systems clear in the rehabilitation of vital infrastructure which had to reopen to traffic in only nine months A powerful earthquake hitting 7.1 on the Richter scale rocked Mexico City and the surrounding area on September 19th, 2017. The devastation was spread throughout Mexico’s capital. [...]

Precastarches.com: Discover our online catalogue and shape calculator for your TechSpan® solutions

A platform dedicated to TechSpan® concrete arches: Visit Precastarches.com to download our catalogue and create your customized TechSpan® project

Reinforced Earth (Pty) Ltd South Africa build on history of Cogmanskloof Pass

Reinforced Earth system with TerraTrel grid facing for historic pass In 1877, using a combination of gunpowder and dynamite, a resourceful pass builder named Thomas Bain blasted the oldest solid rock road tunnel in South Africa and built the Cogmanskloof (or Kogmanskloof) Pass. Between 2016 and 2019, a [...]

Morocco: Sidi Maârouf Bridge is standing tall

Terre Armée and Freyssinet have been involved in the construction of Casablanca’s major new structure, the Sidi Maârouf Bridge. Started in 2015, the cable-stayed bridge is being built as part of the redevelopment of the Sidi Maârouf junction initiated by the city of Casablanca. Funded by the municipality [...]

Canada – new access ramp for the Gardiner Expressway

In Toronto, RECO Canada designed and supplied precast panels for the new gardiner expressway ramp to lower Simcoe Street. Located in the City of Toronto, the York-Bay-Yonge off-ramp to Lower Simcoe street reconstruction project is part of a large push to modernize the waterfront area and accommodate high [...]

Tierra Armada Chile supplies close to 4000m2 of Reinforced Earth® walls for copper mine in Chile

The Spence Growth Option (SGO) project aims to extend the operation of the Spence Mine to more than 50 years, increasing production by approximately 185 ktpa of copper and 4ktpa of molybdenum in the first 10 years of operation. Works include a new 30-metre-high primary crusher, where CAT [...]

TechWall to build iconic walkway at new urban development in Lyon

LYON: Puisoz-Grand Parilly is a new residential, commercial, and business district in one of the regions with the highest urban development by Lyon, France. When completed in 2025, the new neighbourhood will provide 1000 apartments, 23000m2 of office space, and six hectares of public areas. Two thousand people [...]

Canada: RECo participates in Highway 407 East extension

RECo Canada part of one of the largest highway construction projects ever in the province of Ontario.

Nicaragua: Freyssinet – Tierra Armada Panamá at the heart of Managua’s road work

Freyssinet - Tierra Armada Panamá is pursuing its involvement in the road work of the Nicaraguan capital with the building of 3 access ramps. Freyssinet - Tierra Armada Panamá began the second Reinforced Earth® wall project in Nicaragua with the construction of the 7 Sur interchange. Launched in 2017 by national authorities, this [...]

MAGAZINE – Our latest edition is now available!

Do not wait any longer and have a look at the magazine n°231 to keep up with our latest news and projects! You will discover how Terre Armée is contributing to put back in service the Darjeeling Himalayan Railway Toy after a massive landslide by building a 100 [...]

First true abutment in Philippines, a Freyssinet-Terre Armée collaboration

In Philippines, Freyssinet and Terre Armée joined forces to the construction of the Mactan-Cebu Airport Terminal 2 Located 800 km south of the capital of the Philippines, in the city of Cebu, a growing tourist destination, Terminal 2 was achieved and inaugurated in July 2018. Launched in 2015, [...]

Chile: making the 43 highway safer

In central Chile, Tierra Armada has constructed 4 Reinforced Earth walls as part of the extension of Highway 43 that will provide a safe link between the communities of Coquimbo and Ovalle. And consequently bringing to an end the infamous “Road of Death”. This was the Chilean Ministry [...]

Australia: RECo takes part in the massive NorthLink WA project

In Perth, RECo Australia designs and supplies 31,000 m² of TerraTilt® and TerraPlus® facing as part of the NorthLink West Australia road project. In 2016, the city of Perth embarked on highway construction works intended to meet the needs of a rapidly growing population. This large-scale project entitled NorthLink WA will provide the [...]

Canada: Reinforced Earth walls on the Victor Road interchange

In Saskatoon, RECo Canada built 1,080 m² of retaining walls for the new interchange of the city. The company Dream Asset Management and the city of Saskatoon launched an overpass cross highway building project. This interchange that connects Victor Road in the southeast area of Stonebridge to Highway 11 in the City of Saskatoon is aimed [...]

Peru: TechWall® walls for Uchumayo highway

Consisting of a two-lane low-level route for heavy vehicles plus two surface-level connector roads for urban traffic, this project was initially designed with conventional reinforced concrete walls. By proposing an alternative solution based on the use of TechWall® prefabricated walls with counterforts, Tierra Armada generated both time and [...]

Mexico – Stockpile support in San Julian Mine Project in Guadalupe y Calvo

Tierra Armada de Mexico designed and supplied of 1,293 sqm of TerraTrel® retaining wall to support a Stockpile being constructed by The Minera Fresnillo SA de CV CO. This photograph of the site in San Julian Mine Project in Guadalupe y Calvo, Chihuahua (North part of Mexico) shows [...]

Burkina Faso: Terre Armée will enable to ease traffic flow in Ouagadougou

In Burkina Faso, Terre Armée is involved in the construction of Ouagadougou’s northern interchange, creating 12,000 m² of Reinforced Earth® access ramps. The construction works, located in the heart of the city, were commissioned by the Ministry of Infrastructure who awarded the contract to Sogea-Satom (VINCI Construction International Network). The [...]

Chile: Reinforced Earth® walls for the new access road of the town of Iquique

In order to improve the connectivity between the cities Iquique and Alto Hospicio, the Ministry of Public Works of Chile [MOP] developed the basic engineering of the project called "Improving Accessibility and Connectivity of the Iquique city", which is divided into 9 phases. The project, located in the [...]

Diori and Katako interchange projects in Niger

Terre Armée France takes part to the Diori and Katako interchange projects in Niger. In Niamey, capital of Niger, located on the Niger River in the far west of the country, as part of the Diori and Katako interchange projects, Terre Armée France provides the [...]

Terre Armée’s highlights in 2016

An overview of Terre Armée's projects in 2016, among which: - Demir Kapija Bridge, Macedonia - Heads of the Valleys, United Kingdom - Herb Parkway, Canada - La Concordia Bridge, Mexico - SEA high-speed rail line, France - Muak Leak Reservoir, Thailand - The [...]

Venezuela – Reinforced Earth® walls for the “Cinta Costera”

In Vargas State, Freyssinet-Tierra Armada is constructing Reinforced Earth® walls for the new 17-km long seafront In 2016 the Vargas State authorities launched a major project to construct a 17-km seafront in northern Venezuela, between the cities of Punta de Mulatos and Macuto. Freyssinet – Tierra Armada Venezuela was chosen to construct the walls of the works, [...]

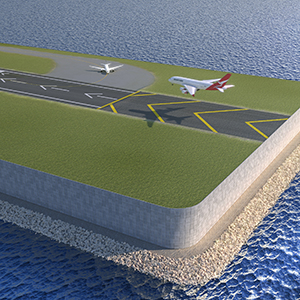

Did you know that Reinforced Earth® retaining walls are an excellent solution for runways extension?

Did you know that Reinforced Earth® retaining walls are an excellent solution for runways extension? Our structures are particularly suited to the constraints related to the construction of new airports including the extension or renovation and upgrade of their take-off and landing runways. Airports are usually located in [...]

Rio de Janeiro – Reinforced Earth walls for the Transolimpica BRT Expressway

On Monday, July 4, 2016, Eduardo Paes, Mayor of Rio de Janeiro (Brazil), inaugurated the new express line BRT (bus rapid transit) Transolimpica. This is, for the Brazilian capital of one of the most important infrastructure in decades. Terra Armada (Brazil), being responsible for the design, supply and [...]

First trials on the new high speed line SEA

First trials on the new high-speed railroad South-Europe-Atlantique (SEA) high-speed line (LGV) linking the city of Tours to Bordeaux have begun and speed will increase up to 352 km/h over the next days on one of the Reinforced Earth® structures supporting a track, where commercial speed of trains [...]

Did you know… that the first Reinforced Earth® true bridge abutment was built in 1969?

Did you know...that the first Reinforced Earth® true bridge abutment was built in 1969? Reinforced Earth structures are able to withstand very high concentrated loads. What is a Reinforced Earth true abutment? A Reinforced Earth bridge abutment which directly bears the load of the bridge deck – no [...]

MEXICO – A new website dedicated to Tierra Armada

The Tierra Armada de México website has been launched. Visit http://www.tierraarmada.com.mx to discover all the information, techniques and projects of our Mexican teams. Follow Tierra Armada de México on social networks! Twitter: @tierraarmadamex Linkedin: Tierra Armada de México Youtube: Canal TierraArmadaMex

Did you know…that Reinforced Earth® structures also work under water?

Did you know...that Reinforced Earth® structures also work under water? Reinforced Earth® structures can be designed to be partially or even fully submerged by water. The stability of the structures is checked for all critical conditions (lowest water level, highest water level, rapid draw down). Effective stresses, pore [...]

France – 15 meters high abutments for national road 82

Located South of Roanne and a hundred kilometers to the West of Lyon, between the towns of Neulise and Balbigny, National Road 82 (RN82) is the last link connecting national road 7 (RN7) to highway A89. On this crucial road to the opening up of the Roanne territory, [...]

United States – RECo provides 290,000 sqm of Reinforced Earth walls for I-4 Ultimate project

The interstate I-4 is a major highway in Central Florida. The Florida Department of Transportation (FDOT) regularly conducts improvement projects on this major axis such as road widening, construction of new roads and improving interchanges. In order to ease the traffic on this 33 km artery more than [...]

Reinforced Earth South Africa takes part to the 1st Southern African Geotechnical Conference

This subregional conference will provide a forum for exchanging, disseminating and discussing current geotechnical practice in Southern Africa as well as sharing information of recent projects and developments. Come and visit us on our booth n°4! The First Southern African Geotechnical Conference will be hosted by the Geotechnical Division of [...]

The Reinforced Earth company (RECO USA) at Geoamericas 2016!

Hosted by the North American Geosynthetics Society (NAGS), the North American Chapter of the International Geosynthetics, the 3rd Pan-American Regional Conference on Geosynthetics is held in Miami, Florida. From April 10th to 13th, The Reinforced Earth Company will present its technical solutions and know how during the exhibition. Come [...]

Russia – Reinforced Earth® ramps for the Kaliningrad stadium

The city of Kaliningrad, Russian enclave between Poland and Lithuania, will host some games of the 2018 FIFA World Cup. As part of this development, numerous structures are being built, including the new stadium of Kaliningrad, named Arena Baltika. Terre Armée France designed 2 060 m² of Reinforced Earth® [...]

DOMINICAN REPUBLIC – TerraClass® access ramps for the Maimón viaduct

As part of an urban highway contours development, Terra Armada (Brazil) completed 5,381 m² of TerraClass® access ramps for the Maimón viaduct. The design of the Reinforced Earth® walls takes into account seismic effects and includes specific steel strips as reinforcements. Terra Armada was responsible for the design, material supply and on-site technical assistance. [...]

Terre Armée at the XV PCSMGE in Buenos Aires

The 15th PCSMGE (Pan-American Conference on Soil Mechanics and Geotechnical Engineering) will be held from November 15th to 18th at the Hilton Buenos Aires in Argentina. This show is an opportunity for Terre Armée to showcase its expertise in reinforced backfill applications and in soil-structure interaction. In order to know [...]

Terre Armée at the 15th ARC 2015 in Fukuoka

The 15th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering will be held in Fukuoka, from November 9th to 13th at the Fukuoka International Congress Center. The theme of this edition will be "New Innovations and Sustainability". To learn more about the different techniques and applications in [...]

Terre Armée at WRC 2015 in Seoul

The 25th World Road Congress will be held in Seoul, from November 2nd to 6th at the Coex convention center. The focus of this edition will be on "Roads and Mobility - Creating New Value from Transport". To learn more about the different techniques and applications in which Terre [...]

DENMARK – The first high speed railway has Reinforced Earth® true abutments

In order to widen its rail network, Denmark will get equipped with its first high speed rail line. This project have started with the new line Copenhagen-Ringsted and will continue within Denmark. Furthermore, this high speed rail network will enable southern Danish regions to be connected to Germany [...]

SERBIA – Access ramps in Reinforced Earth® for the bridge Europa in Novi Sad

This summer, Freyssinet Ogranak Belgrade achieved the construction of the two access ramps in Reinforced Earth® for the Bridge Europa in Novi Sad, Serbia. Terre Armée France, who was in charge of the design and supply of materials and molds, proposed Geostrap® strips with TerraPlus® concrete panels in order to have the [...]

LESOTHO – A TerraTrel® bridge near Koma Koma Village

Taking place in a very remote site at 230km from the capital Maseru, this project was awarded by the Lesotho Ministry of Public Works & Transports (Roads Directorate). Reinforced Earth South Africa was in charge of designing and supplying RE materials for the two Reinforced Earth® abutments. The aim [...]

USA – Bay Area Transit (BART) – Warm Springs Extension

Major construction on the Warm Springs Extension in Fremont, CA began in August of 2009 and will continue until the fall of 2015. This project will add 5.4-miles of new track south from the existing Fremont Station to a new station in the Warm Springs District of the [...]

BRAZIL – Terra Armada Ltda. celebrated its 40th anniversary !

Founded in Rio de Janeiro in August 1975, Terra Armada has a portfolio of nearly 800 completed works, with a total facing area of more than one million sqm. Among our most significant works, we highlight the TerraClass dump wall of the "Cauê Project", in the State of Minas Gerais. [...]

Terre Armee at the 25th ICOLD congress from june 13rd to 20th

The 25th Congress of the International Commission on Large Dams will take place in Norway and represents an opportunity for Terre Armee to showcase its expertise in dams and hydraulic structures. Stop by our booth #35 at Stavanger Forum! For more information, browse our brochure Dams and Reservoirs. [...]

Las Tórtolas tailing dam

Background In October 2007 Anglo American approved an investment of US$2.4 billion to expand its Los Bronces open cut copper and molybdenum mine, high in the Andes Mountains of Chile. The expansion includes new grinding facilities in the Confluencia sector, a flotation plant at Las Tórtolas (Colina) and [...]

World Premiere: Reinforced Earth® equips the high-speed railway lines

The construction of Reinforced Earth® walls for the South-Europe-Atlantique (SEA) high-speed line (LGV) linking Tours to Bordeaux was completed in September 2014. Eleven structures totalling 20 walls were built, mainly to support the railway tracks on both sides of flyovers. The highest structure is 12.70 m high. For two of [...]

RECO won The Concrete Institute of Australia Branch’s award

The Concrete Institute of Australia Branch held their Annual Dinner last Friday 31st October 2014 in Perth. RECO is very proud to announce that we won an award on the night. The award was for the design and construction of a Reinforced Earth® TechSpan® arch at Mining Area [...]

Nigeria – Third interchange project for Reinforced Earth

Bayelsa is a state of southern Nigeria in the core Niger Delta region. It has one of the largest crude oil and natural gas deposits in Nigeria. As part of the massive infrastructure modernization in Yenagoa, the capital of Bayelsa, 2 new interchanges will be created at each end of [...]

When Terre Armée delivers Reinforced Earth walls for the Winter Olympics

In the course of numerous infrastructure projects for the 2014 Winter Olympics in Sochi (Russia), a new 48 km long transport link between the city of Adler on the Black Sea and Krasnaya Polyana in the Caucasus was built. This transport connection consists of a highway & a railway line. [...]

Chile – Bridge abutments in Reinforced Earth on a crossroad

In Chile Tierra Armada teams have achieved the construction of 2 Reinforced Earth® bridge abutments on a exchanger being constructed on the Route 160. These walls consist of 2,836 m² TerraClass® walls with galvanized steel strip reinforcements. More about: Roads & Motorways Download [...]

Access ramps in Reinforced Earth for the bridge over Rio Madeira in Brazil

The construction of the first bridge over the Madeira River near Porto Velho (capital of the state of Rondônia), has been completed. The work, which began in May 2010, was interrupted several times, notably because of the speed and velocity of the river water (about 4 m / s). [...]

Thailand – Widening Highway 11

To manage increased traffic flow on Highway 11 connecting the cities of Uttaradit and Denchai in the North of the country, the Department of Highways decided to widen this route passing through mountainous country from two to four lanes. To avoid the need for large volumes of backfill [...]

Croatia – Sveta Trojica wall

1 km West of the village of Križišće stands the imposing Reinforced Earth® structure of Sveta Trojica: A three-tiered wall with max. height 34 m and 375 m long. The total surface area is 11,170 m². Terre Armée designed the structure and supplied the GeoStrap® reinforcements, and connections. More about: Roads [...]

AUSTRALIA – Regional Rail Link, West Werribee Junction

The Regional Rail Link Project, located in the Victoria state, has been inaugurated this year. For this significant project, RECO Australia provided several Reinforced Earth® structures. On the West Werribee Junction section, RECo Australia was required to design and supply two Reinforced Earth® retaining walls and six flyover walls for a total surface of 5,517 m². [...]